Introduction

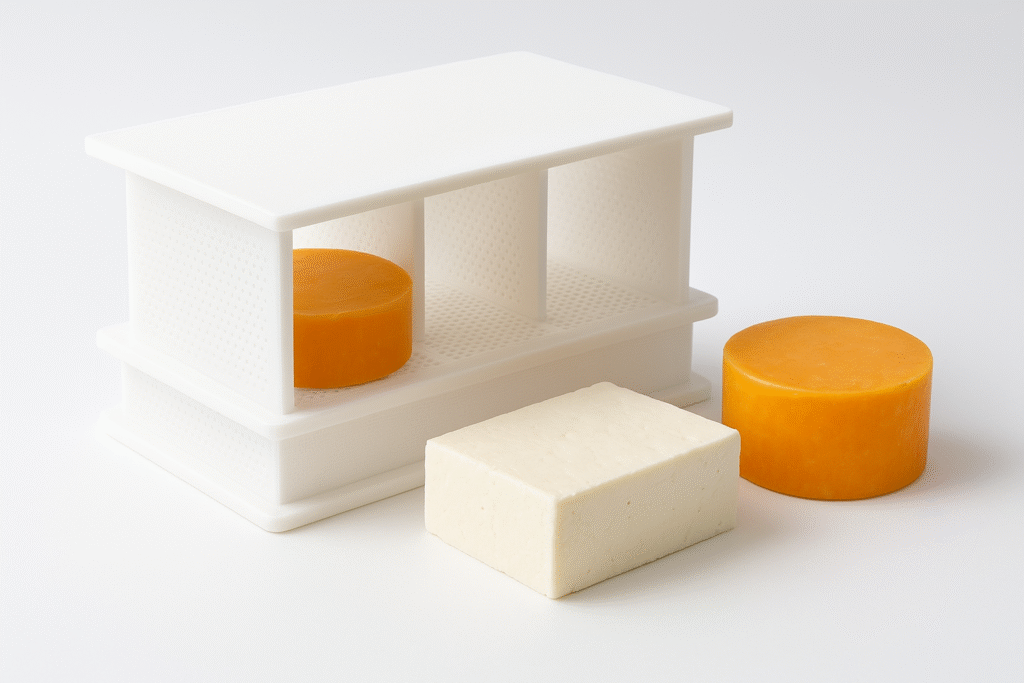

Cheese moulds are essential in shaping the texture, consistency, and quality of cheese. Whether you’re making cheddar, paneer, or artisanal cheese, selecting the right cheese mould ensures the perfect balance of moisture, firmness, and uniformity.

Why Cheese Moulds Are Essential for Better Texture

- Moisture Control for Consistent Texture

The perforations in cheese moulds regulate whey drainage, ensuring optimal moisture levels. Too little drainage results in soft cheese, while too much leads to crumbly texture. Proper whey removal is key to achieving the right cheese consistency. - Uniform Pressure Distribution

Even pressure helps prevent cracks or weak spots, ensuring a consistent texture throughout the cheese block or wheel, which is essential for high-quality production. - Shape Retention

The cheese mould defines the shape and supports curds during pressing, ensuring uniformity and consistent shape retention throughout the process. - Production Efficiency

Well-designed cheese making moulds improve efficiency, reduce waste, and speed up the cheese-making process, which is crucial for both artisanal and commercial producers.

Popular Cheese Moulds

- Block Moulds – Perfect for cheddar and paneer, ensuring consistent, sturdy shapes.

- Round Moulds – Ideal for traditional rounds with smooth surfaces and even drainage.

- Euro Honeycomb Moulds – Special perforation for faster whey removal and firmer texture.

- Multi-Cavity Moulds – Produce multiple small cheeses at once, saving time for high-volume production.

Explore our full Cheese Mould range for more options and find the best cheese moulds for artisanal and commercial cheese making.

Certified for Safety and Quality

Choosing the right mould also ensures hygienic processing and compliance with international standards. High-quality moulds meet global food safety certifications, including:

- FDA – Food safety compliance

- CE – Conformity with European safety standards

- ROHS – Restriction of hazardous substances

- FSSC 22000 – Food safety management systems

These certifications confirm that the moulds are suitable for both artisanal and commercial cheese production, ensuring food-safe, high-quality cheese moulds for consistent results in every batch.

Explore More

Check out our related blogs to learn more about cheese moulds and how they improve quality and yield:

- How the Right Cheese Mould Boosts Quality, Texture & Yield Precision Cheese Moulds by DAPL

- Top 5 Types of Cheese You Can Perfectly Make with Our Premium Cheese Moulds

Ready to improve your cheese texture and production? Contact us today for expert advice on choosing the perfect cheese mould to boost your cheese making efficiency and quality.